Call Us Today 1-830-775-1417

Call Us Today 1-830-775-1417

Call Us Today 1-830-775-1417

Call Us Today 1-830-775-1417

The engineers at Backer Marathon have developed a swaged cartridge heater that exceeds the performance and durability of others in the industry.

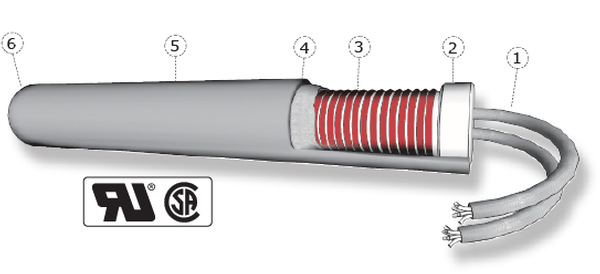

Through refinements in the swaging process, specially designed cores, careful selection of magnesium oxide fill, nickel chromium resistance wire, stainless steel tubing, and carefully controlled production processes, HotRod cartridge heaters routinely outperform other heaters in difficult applications.

HotRod cartridge heaters are available in a wide variety of diameters and configurations. Choose from our 14,000+ stock heaters for immediate delivery or let the engineers at Backer Marathon design a unique cartridge heater for your special application. Standard manufacturing times are normally less than 2 weeks.

HotRods are UL recognized, File #E202904 and RoHS Compliant.

| Part No. | Diameter | Watts | Volts | Length | Available Qty | Price |

|---|---|---|---|---|---|---|

| HR10035A | 1.000 inches | 600 watts | 240 volts | 3.50 inches | 7 | Sign In for Pricing |

| HR10035D | 1.000 inches | 600 watts | 240 volts | 3.50 inches | 11 | Sign In for Pricing |

| HR10035E | 1.000 inches | 600 watts | 240 volts | 3.50 inches | 2 | Sign In for Pricing |

| HR25010H | 0.250 inches | 55 watts | 120 volts | 1.00 inches | 0 | Sign In for Pricing |

| HR25010J | 0.250 inches | 100 watts | 120 volts | 1.00 inches | 1 | Sign In for Pricing |

| HR25010K | 0.250 inches | 100 watts | 240 volts | 1.00 inches | 0 | Sign In for Pricing |

| HR25010L | 0.250 inches | 150 watts | 120 volts | 1.00 inches | 13 | Sign In for Pricing |

| HR25012F | 0.250 inches | 100 watts | 120 volts | 1.25 inches | 15 | Sign In for Pricing |

| HR25012G | 0.250 inches | 150 watts | 120 volts | 1.25 inches | 0 | Sign In for Pricing |

| HR25012H | 0.250 inches | 150 watts | 240 volts | 1.25 inches | 1 | Sign In for Pricing |

| HR25012T | 0.250 inches | 75 watts | 120 volts | 1.25 inches | 5 | Sign In for Pricing |

| HR25015AU | 0.250 inches | 150 watts | 240 volts | 1.50 inches | 2 | Sign In for Pricing |

| HR25015K | 0.250 inches | 100 watts | 120 volts | 1.50 inches | 2 | Sign In for Pricing |

| HR25015L | 0.250 inches | 150 watts | 120 volts | 1.50 inches | 0 | Sign In for Pricing |

| HR25015M | 0.250 inches | 200 watts | 120 volts | 1.50 inches | 0 | Sign In for Pricing |

| HR25015N | 0.250 inches | 200 watts | 240 volts | 1.50 inches | 0 | Sign In for Pricing |

| HR25015Y | 0.250 inches | 200 watts | 240 volts | 1.50 inches | 7 | Sign In for Pricing |

| HR25017B | 0.250 inches | 200 watts | 240 volts | 1.75 inches | 5 | Sign In for Pricing |

| HR25020AC | 0.250 inches | 200 watts | 240 volts | 2.00 inches | 0 | Sign In for Pricing |

| HR25020AX | 0.250 inches | 40 watts | 120 volts | 2.00 inches | 7 | Sign In for Pricing |